Knowledge Base +

Knowledge Base +  2024.01.10

2024.01.10LC (Lucent Connector), FC (Fiber Channel), and SC (Subscriber Connector) are three common types of fiber optic connectors, and they differ in terms of size, latch mechanism, and typical applications.

This table of common connectors gives an overview of strengths and weaknesses, with more detail in the accompanying descriptions:

| Name | Mating Cycles | Ferrule Size | Typical Insertion Loss (db) | IEC Spec | Cost | Ease of Use | Application Features |

| SC | 1000 | Ø2.5mm Ceramic | 0.25 - 0.5 | 61754-4 | $$ | •••• | Mainstream, Reliable, Fast deployment, Field fit |

| LC | 500 | Ø1.25mm Ceramic | 0.25 - 0.5 | 61754-20 | $$ | •••◦ | High density, Cost effective, Field fit |

| FC | 500 | Ø2.5mm Ceramic | 0.25 - 0.5 | 61754-13 | $$$ | ••◦◦ | High precision, Vibration environments, Field fit |

| ST | 500 | Ø2.5mm Ceramic | 0.25 - 0.5 | 61754-2 | $$$ | ••◦◦ | Military (legacy), Field fit |

| MPO/ MTP | 1000 | 6.4 x 2.5 mm Composite | 0.25 - 0.75 | 61754-7 | $* | •••◦ | High density, Aggregate networking, Fast deployment |

| MDC | 500 | Ø1.25mm Ceramic | 0.25 - 0.5 | N/A | $$$ | •••◦ | Very high density duplex / transceivers |

| HFOC | 500 | Ø2.5mm Ceramic | 0.25 - 0.5 | N/A | $$$ | •••◦ | Hardened outdoor FTTH drops |

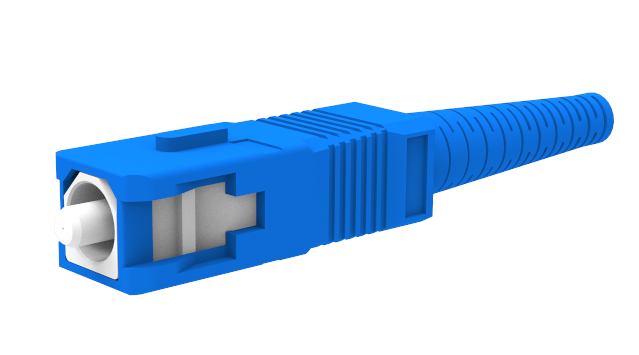

SC Connector

The SC was developed by the laboratories at Nippon Telegraph and Telephone (NTT) in the mid-'80s, and was one of the first connectors to hit the market following the advent of ceramic ferrules. Sometimes referred to as the ‘square connector’ the SC has a push-pull coupling end face with a spring-loaded ceramic ferrule. Initially intended for Gigabit Ethernet networking, it was standardized into the telecommunications specification TIA-568-A in 1991 and slowly grew in popularity as manufacturing costs came down. Due to its excellent performance, it dominated fiber optics for over a decade with only the ST rivalling it. It remains the second most common connector for polarization maintaining applications. The SC is ideally suited for datacoms and telecoms applications including point to point and passive optical networking.

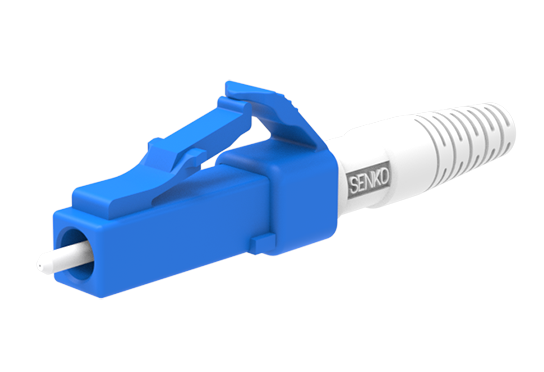

LC Connector

Considered by some to be the modern replacement of the SC connector; its introduction was less successful, in part due to initially high license fees from inventor Lucent Corporation. Also a push-pull connector, the LC utilizes a latch as opposed to the SC locking tab and with a smaller ferrule, it is known as a small form factor connector. Having half the footprint of the SC connector gives it huge popularity in datacoms and other high-density patch applications, as its combination of small size and latch feature make it ideal for densely populated racks/panels. With the introduction of LC-compatible transceivers and active networking components, its steady growth in the FTTH arena is likely to continue.

FC Connector

The FC was the first optical fiber connector to use a ceramic ferrule, but unlike the plastic-bodied SC and LC, it utilizes a round screw-type fitment made from nickel-plated or stainless steel. The connector end face relies on an alignment key for correct insertion and is then tightened into the adapter/jack using a threaded collet. Despite the additional complexity both in manufacturing and installation, it’s still the connector of choice for precise measuring equipment such as OTDRs.

Initially intended for datacoms and telecoms applications, its use has reduced since the introduction of the SC and LC. These deliver similar performance to the FC, but both have less expensive components and are quicker to connect. However, the screw-on collet of the FC does make it particularly effective in high vibration environments, ensuring that the spring-loaded ferrule is firmly mated.

Subscribe to the newsletter

for all the latest updates.

2-5# Building, Tongfuyu Industrial Zone, Aiqun Road, Shiyan Street, Baoan District, Shenzhen. China